Over the past year, we have been trying to understand what the UK food and drink industry is doing to combat climate change and eliminate waste.

There are many organisations and pressure groups. There is new legislation coming in on EPR, DRS and collection. And food manufacturers such as Unilever and Coca-Cola are saying they won’t meet the targets they set themselves. It’s confusing for people in the industry, let alone the public.

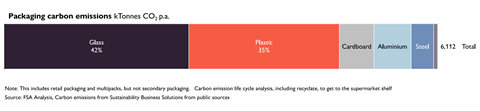

So we decided to assess the amount of packaging used in the supermarkets using two key measures: carbon emissions and circular recycling. (Ocean pollution and water usage are important too, but harder to quantify.)

The results we found were surprising on a number of levels: the first standout statistic is that glass makes up two-thirds of the weight of packaging in supermarkets.

You might say “that’s great!” because it’s a recyclable material and is being recycled a lot. But the carbon emissions story is not so rosy. Due to its weight, and because it takes a lot of energy to melt for recycling, glass carbon emissions are high. In fact, glass makes up two-fifths of the carbon emissions associated with the packaging on UK supermarket shelves.

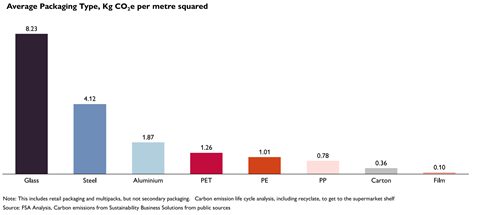

As retailers and suppliers weigh up these considerations, one factor to look at is how materials can be substituted, while also keeping in mind their functional properties. We assessed the average wall thickness seen in supermarket packaging to work out the carbon emissions for each material per square metre, assuming that each can hold the same amount of product.

That’s when amazing statistic number two struck us: we found that film uses 1/80th of the carbon emissions of glass and carton uses 1/20th.

Ardagh is now working on a low-carbon method for producing glass, which uses 80% electricity rather than 80% natural gas for heating. O-I Glass has announced a bottle with 22% less glass and 25% lower carbon emissions.

But the data shows that if we replaced all the glass in the supermarket with a combination of film and carton (such as bag-in-a-box), we could reduce carbon emissions by 40%. For example, Frugalpac has a carton and film bottle which has 84% less carbon emissions than a standard glass bottle.

Is film the best material?

But of course, CO2 is only part of the story. So our analysis also looked to address the question of circular recycling, so we don’t use up the planet’s finite resources and destroy wildlife or clog up our arteries with nanoplastics.

| Food | Sorting | Recycling | Economics | Virgin material |

|---|---|---|---|---|

| Food approval | Lightweight, small, coloured materials | Recycling degradation/contamination | Collection/distribution logistics | Scarcity |

| Non-food applications | Detection of different films | Multilayered | Supply/demand economics of recyclate | Cost |

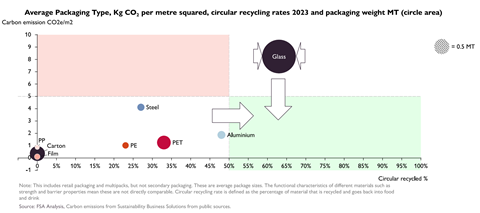

So we calculated the circular recycling rates for different materials. And this is where it gets more complicated. We identified a need to assess a number of factors, such as food approval, the use of multilayered materials, and recycling degradation. As the chart below shows, it depends on the packaging type.

| Glass | Aluminium | Steel | PET | PE | Carton | Film | PP |

|---|---|---|---|---|---|---|---|

| 70% | 70% | 30% | 25% | 20% | 0% | 0% | 0% |

| Colour sorting | Collection rate | Tin contamination | Pots/trays/tubs sortation | Food approval | Fibre shortening | Food approval, multilayer | Food approval |

But with a clear need for a combined view of carbon emissions and circular recycling, it’s possible to plot the situation and the opportunities.

The chart above shows there is no ideal material in the sweet spot. Glass carbon emissions are too high. Steel, aluminium, PET and HDPE circular recycling rates are too low.

But the zero circular recyclability of carton, film and possibly polypropylene (PP) are significant opportunities. Progress is being made: some important substitutions have taken place recently. To reduce carbon footprint, carton, film and PET are being introduced on a small scale for wine. And there is more film being used in fresh meat.

To improve recyclability, PET is now used in yoghurt cartons, and the Faerch CPET used in ready meal trays is now recyclable. We can make a large difference if glass is replaced or made much lighter to reduce carbon emissions – and if we fix carton and film so they are circularly recycled. On top of that, we need the collection and sorting of pots, tubs, trays and film to improve recycling rates.

The message is: less glass and circularly recyclable film and carton. Let’s get to work on this quickly.

2 Readers' comments