Welsh startup Mona Island Dairy is investing £20m to build what it is claiming will be Europe’s most sustainable cheese factory.

The Anglesey-based business will complete work on the 25,000 sq ft facility near Holyhead in September, with the creation of 100 jobs.

The project will see the company manufacture up to 7,000 tonnes of premium own-label Welsh and continental cheese a year. Products made at the plant will include cheddar, gouda, edam and a range of artisan cheeses, using milk sourced from about 40 family farms based across the north of Wales and overseen by chairman and local dairy farmer David Wynne-Finch.

Fronted by dairy industry veteran and MD Ronald Akkerman, Mona Island Dairy is funded through a combination of private investment, loans and a £3m grant from the Welsh government’s business innovation and tourism escalator scheme (BITES). It will aim to target the own-label cheese market via supermarkets and foodservice operators initially, but also has plans to launch branded cheese within the next two years.

The plant would run solely on renewable electricity, Akkerman said, while he expected to see turnover rise to £25m by 2022. He added the plant would “set new standards for the industry” as it blended both innovative and traditional cheesemaking methods.

Customers would be able to “choose the type of cheese (brine or dry salted), the fat content, the shape (block or traditional wheel) and have the option of selecting additional ingredients such as herbs and spices”, he added.

“This will result in premium own-label products being produced in significant volumes or in relatively small batches,” Akkerman said.

“Different milk streams can be processed into specific niche products, such as organic cheese. Biodegradable wastes such as milk residue will be processed at the nearby Mona Biogas plant on Anglesey and all the process water will be recovered from the whey concentration, thereby minimising the intake of potable water. This will make it the most environmentally-friendly factory in Europe.”

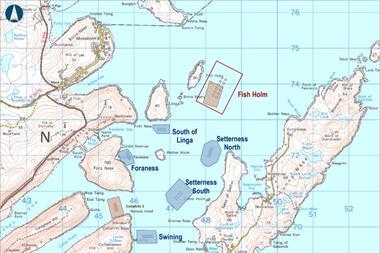

On the map: Welsh food and drink category report 2020

Another unique element to the project was through its collaboration with academia, with Wrexham Glyndwr University Business School and Coleg Menai in Llangefni on Anglesey providing courses, apprenticeships and technical advice for the new venture.

Given the implications of Brexit on cheese imports, the factory would look to meet demand from customers looking to switch to UK-manufactured cheese, suggested director Graham Jackson, who is also a professor at the Glyndwr University Business School.

“Brexit helped enormously to give everyone the motivation to push on with the project. This is a unique proposition and the first major new cheese factory in Europe to be built in some time,” he said.

“This is the largest new development in the food sector in North Wales this year and is attracting an enormous amount of interest across the dairy and cheese industry in the UK and Europe,” added Akkerman.

“Linking the Welsh government with academia and entrepreneurs in the region has formed a strong triple helix that will help to get the economy going again. The focus will be to develop long-term partnerships with anchor customers and milk suppliers – it’s an exciting project, fantastic for the industry and the region.”

The project represents a boost for the Welsh dairy sector following the closure of Arla’s Llandyrnog creamery in 2018 and the collapse of Wrexham-based liquid milk processor Tomlinson’s Dairies in 2019. It was described as “excellent news for Holyhead, Anglesey and the wider area” by Lesley Griffiths, the Welsh minister for rural affairs and north Wales.

“It is good to see that milk from local farms will be used in the production of the cheese, which will be a boost for the dairy industry, and it is great to see the measures taken to minimise the impact on the environment.”

No comments yet