From Tesco to Hovis, leading retailers are rethinking how they manage road transport. Here’s how technology is helping them navigate complexity and deliver results.

Most people don’t stop to think about how their favourite products or household essentials make it from the farm, the field or the factory to that perfect spot in store. Yet, behind every pint of milk or loaf of bread is a complex web of logistics, working quietly out of sight to make sure it’s there when you want it.

Elsewhere, keeping retailers happy with how their goods arrive – no matter their size – is anything but simple. Even the best plans can be thrown off by countless variables, many of them unpredictable and beyond anyone’s control, all of which can impact delivery times.

When it comes to road transport and haulage, retailer satisfaction hinges on two essentials: powerful tracking technology and precision planning that keeps operations running at their best.

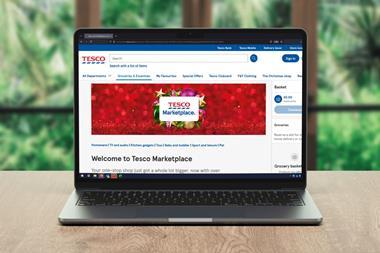

Take Tesco, for example. With over 2,500 trucks and 4,000 trailers, it runs one of the largest HGV fleets in the UK. Managing such a vast operation means tracking every vehicle in real time, maintaining rigorous safety and maintenance standards for both trucks and drivers and cutting down on empty runs – a complex set of demands by any measure.

By integrating Microlise’s advanced fleet technology, Tesco completely transformed its delivery operation. Real-time tracking pinpoints the exact location of every vehicle, keeping schedules on track, while a driver performance app provides instant feedback, helping drivers improve and achieve peak performance on every journey. Additionally, fleet safety management tools track fuel usage, spotting ways to boost efficiency, cut consumption and lower costs.

“Microlise, as an end-to-end transport solution, specifically the Schedule Execution Board (SEB) really gives us the visibility and the ability to report on our delivery on time performance,” says Chris Jones, Tesco’s regional transport manager north and head of fuel logistics.

Since adopting the system, Tesco has seen outstanding results, delivering 99% on time to large stores and 96% to convenience stores.

“That’s a clear reflection of the efficiency improvements we’ve been able to make using Microlise as an end-to-end transport solution,” adds Tesco’s Chris.

The driver app has encouraged smoother, more efficient driving and boosted road safety, while the telematics system has helped cut emissions, sharpen hazard awareness and improve forward planning.

“It’s really important we continue to use the Microlise system to continue to improve our drivers scores, to continue to improve that MPG that we deliver and the associated emissions that reduce as a result,” adds Jones.

Operationally, Jamie Futcher, lead transport manager says, “I can’t imagine what my day would look like without the Microlise system, it really does give us everything we need to run an operation this big.”

Similarly, Hovis turned to the UK’s leading road transport solutions provider to help manage its complex supply chain. Each year, the company makes around 1.2 million customer deliveries, supported by a fleet of 250 trailers and roughly 400 vehicles.

Hovis enhanced its telemetry with Microlise’s Journey Management solution, tapping into the power of its Schedule Execution Board (SEB). This tool improves customer communication and provides a clear view of fleet performance against the original plan, using simple colour codes to show whether deliveries are running early, on time or late.

“We operate a massive supply chain operation for 365 days a year, covering over 20 million road miles and delivering in and out of major towns and cities, which is a challenge,” says Adam Bassant, the bakery’s logistics director.

“We base our whole logistics operation around the Microlise solution. I couldn’t envisage running our business without having the right telemetry and data tools in place,” he adds.

“Microlise allows us to say to our customers that they will get this amount of product, on this day, at this time, and that absolutely sets us apart from the rest. It gives our customers complete confidence and the assurance that we will do exactly what we say we’ll do,” says Ross Burford, logistics operations manager.

Proof of Delivery (POD) can also be a challenge for transport operators. In its industry report, Standing at the Crossroads: A Crucial Moment for UK Logistics , Microlise surveyed 250 transport and logistics managers and found that manual Proof of Delivery processes are riddled with issues for both operators and customers. Operators shared stories of customers unable to read a driver’s handwriting on POD documents, and disputes over delivery condition with no evidence to determine who was at fault.

SmartPOD, Microlise’s fully digital solution, removes problems caused by traditional paper-based POD. Adopted by Waitrose to remove any uncertainty around deliveries, it also brings a host of additional benefits. “Our business greatly benefits from SmartPOD as an excellent dispatch tool,” says Paul Edwards, TMS change agent at Waitrose & Partners.

“It is fully configurable and includes vehicle checks. We feel like we are increasing the value we get from the system every day by working with our account manager, who helps us learn more about data and increasing efficiency. I feel like Microlise has become part of our family,” he concludes.

To bring Microlise’s award-winning, top-ranked fleet solutions into your business, visit www.microlise.com.